Installing BCM Balluff condition monitoring sensors

For secure and lasting installation of the BCM the sensor must be attached directly on the machine or relevant component to be monitored. To ensure the best possible signal quality, we recommend tightening the sensor using screws (see section direct installation). Alternatively, the sensor can be temporarily attached to the surface using a magnetic holder (see section installation with magnetic holder).

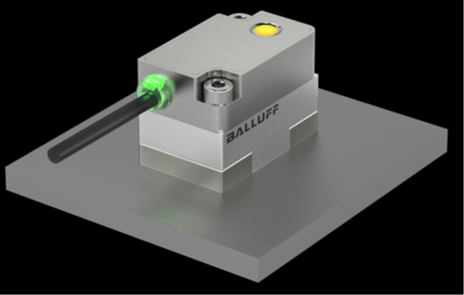

Direct installation:

For mounting in a threaded or a through hole, two M3 screws are required.

Prerequisites for direct installation:

- Sufficient wall thickness of the component.

- The installation surface must not be curved or uneven.

- Set up an installation surface of at least 32 × 20 mm.

- Create two vertical drilled holes with an M3 internal thread or a corresponding through the hole that fits to the mounting holes of the BCM in the installation surface (for dimensions, see Figure given above).

- Clean the installation surface.

- For improved heat conduction, apply a thin film of a thermo conductive medium.

- Align the BCM with the installation surface according to the threaded holes and tighten them until they are hand-tight using the fastening screws.

- Tighten the fastening screws.

- Check that the BCM is fastened securely.

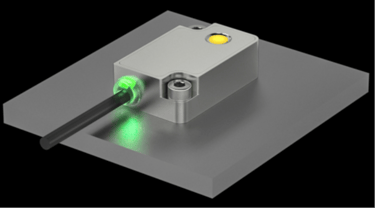

Installation with magnetic holder:

The sensor can also be temporarily attached to the surface using a magnetic holder. This requires a magnetic holder on which the sensor is installed.

Prerequisites for installation with magnetic holder:

- The installation surface must be ferromagnetic.

- The installation surface must not be curved or uneven.

- Clean the installation surface of the magnetic holder for the BCM as well as the BCM underside.

- For improved heat conduction, apply a thin film of a thermo conductive medium.

- Align the BCM with the magnetic holder according to the threaded holes and tighten using the fastening screws at tightening torque of 1.2 Nm.

- Check that the BCM on the magnetic holder is secure and readjust, as necessary.

- Set up an installation surface of at least 32 × 20 mm and clean it.

- Attach the BCM to the installation surface using the magnetic holder.

- Check that the magnetic holder on the installation surface is secure and change the mounting location, as necessary.