Balluff's conveyor error proofing solution

When a Tier 1 automotive chassis component manufacturer needed to implement an Error Proofing System, they turned to their conveyor OEM and their control systems integrator for help.

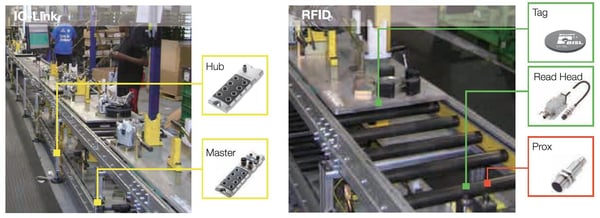

They needed to be able to track pallets through the test stations and control the pallet movement with sensors and solenoids.

The conveyor itself presented the next challenge since it was a bi-level conveyor system with the upper level for assembly and the lower level for pallet return, causing limited space for associated controls hardware and mounting. With these space constraints, traditional installations via conduit, terminal blocks and junction boxes would be bulky and not feasible.

The third and most difficult challenge came with the demands of production and delivery, leaving little time for the integration of the technology, and a tight scheduling window available for installation and commissioning.

This combination of challenges drove them to investigate compact and quick to install distributed modular I/O solutions.

Benefits of Balluff IO-Link and RFID

■ Easily integrated pallet tracking with RFID technology tied into the distributed modular I/O system.

■ Eliminated the need for junction boxes and terminal wiring, dramatically reducing the physical footprint of the controls.

■ Ability to meet the short installation timetable due to multiple factors including: Small and distributed components allowed machine mounting in available spaces.

■ Available Add-on-Instructions(AOIs)allowed for fast and easy software integration.

■ Standard cordsets and connectors made for fast physical installation at the site.

■ A side benefit of this open and vendor neutral control architecture was on future projects different PLC control platforms could be deployed and hardware design would remain the same.

Learn more about Balluff's conveyor error proofing solution