The pressure and level measurement solution

Application examples:

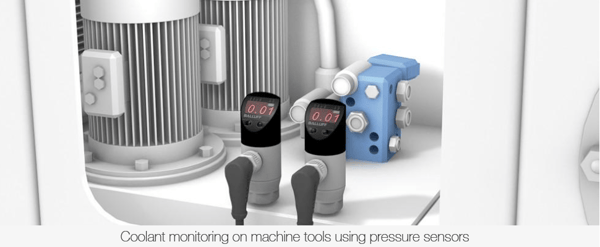

Consistently high surface quality of the machined work piece must be ensured in a machine tool. This requires continuous monitoring of the coolant feed system pressure. Pressure sensors can reliably monitor the pressure and shut down the machine within a few milliseconds when the defined pressure range is violated.

In many tanks and vats the fill height of the liquid must be continually measured. This is accomplished using ultrasonic sensors, which make it possible regardless of color, transparency or surface composition of the medium. These sensors detect objects made of virtually any material (including sound-absorbing) such as liquids, granulates and powders.

The Solution:

Pressure sensors are widely used in process and factory automation, including for pressure regulation in tanks and distribution systems. The monitoring of process media such as coolants, hydraulic fluids and pneumatic has an important effect on the production processes.

For level measurement sensors having various operating principles can be used:

Ultrasonic sensors are installed above the tank, and have no contact with the medium.

Capacitive sensors are installed above the tank, and have contact with the medium.

Magnetostrictive sensors can extend from the top to the bottom of the tank. The magnet (position marker) has contact with the medium.

Learn more about Balluff's pressure and level measurement solution