The advantages of IO-LINK Masters

1. IO-Link System

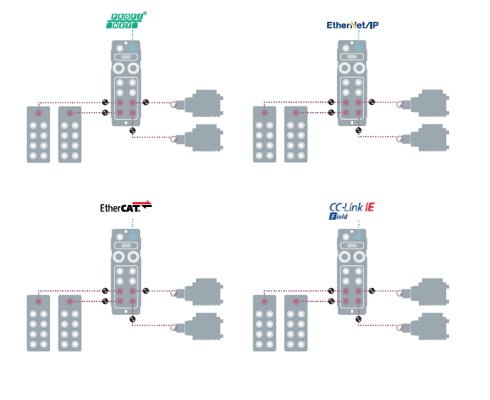

A communication standard embedded in sensors and actuators which are connected via a Master. The Master then will send the device data to a controller (PLC, HMI, etc. ) through an industrial Ethernet protocol such as Ethernet/IP, Profinet, CC-link-IE.

The advantage of the IO-Link products:

- Data Storage

- Remote Parameterization

- Advanced Diagnostics

- Reduced Wiring

2. Balluff's IO-Link Master's Benefits

Balluff's IO-Link Masters allow IO-Link device communication to multiple industrial Ethernet protocols: all simultaneously!

- Use Cases:

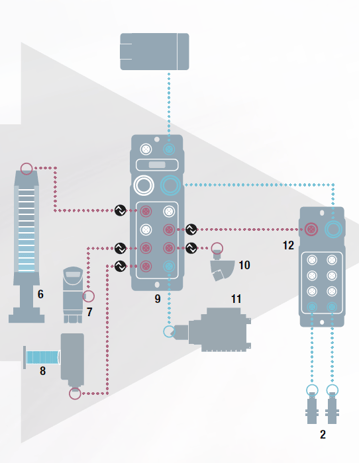

- Provide simultaneous data to the PLC and HMI, using different protocols

- Communication to Ethernet/IP or Profinet controllers, and the actutor voltage UA Clients separately

- Reduce the amount of data being pushed through one controller to others

3. Process Data Storage

Allows an IO-Link device to be automatically configured using previously stored values. Quick and easy replacement of failed or damaged sensors/ actuators, which means reduced downtime and maintenance costs. IO-Link devices have to be v1.0 or v1.1 or greater to use this feature.

Example: Company A has IO-Link v1.1 sensors deployed and Data Storage enabled in the Web server page. If an IO-Link device needs to be replaced, a factory default device of the same type can be connected and automatically configured.

4. Online Parameterization

Balluff’s IO-Link Master enables remote communication from a control system to an IO-Link device for parameter changing. Tools and files are available depending on the protocol used.

In addition, you can change an IO-Link device’s configuration using the Balluff IO-Link Master web interface without a PLC or HMI. Both PDI (process data input) and PDO (process data output) parameters can be changed.

- User Benefits:

- Perform common device setting changes a variety of ways, no manual configuration

- Reconfigure IO-Link devices in hard-to-reach or hazardous areas

5. Data Types: Process, Service, Event

Three types of data are visible with IO-Link:

- Process Data,

- Service Data

- Event Data.

- Process Data: Also referred to as cyclic data. This is information that a device is intended to deliver or measure such as temperature, distance, proximity, flow rate, etc.

- Service Data: All data that is not relative to the process data and also known as acyclic data. Manufacturer name, device description, model number, serial number, etc.

Parameter values are also listed which can be changed in the Comtrol interface or controller program. - Event Data: Notification or flag created when a critical event occurs. Examples of event data could be: wrong sensor connected, communication error, open circuits, overload, dirty lens.

6. IODD: IO Device Description

Every IO-Link sensor/actuator has an IODD file which contains device information and parameter values. These files can be loaded on a web interface such as Balluff’s. Each IO-Link device manufacturer will have these available on their website.

With Balluff’s IO-Link Masters you can load and store a library of IODD files onto the Balluff IO-Link Master so that you can access device information and parameters easily through Balluff’s IODD Handler.

7. Reduced/Simplified Wiring

There are a number of ways IO-Link offers reduced or simplified wiring:

- Standard M12 cables are used in almost all applications

- Less cabling and space occupied in cabinets when using M12 IP67 out-of-cabinet Masters

- Multiplex Digital and Analog I/O with IO-Link hubs, reducing cabling in and out of cabinet

- Reduction in wiring for some IO-Link devices such as motor starters and push buttons

8. Clone Configuration

With IO-Link devices, you can back them up and replace/ replicate settings easily. What about the IO-Link Master?

- Loaded IODD Files

- Data Storage for sensors

- Block Configuration Settings

The selected settings will then save to a file on the user’s computer, and can be loaded to a new Master, or to rapidly mass commission sets of Masters with the same or similar settings required.

9. Device Validation

Allows the user to choose if a port on Balluff’s IO-Link Master will work with any sensor, a sensor brand/type, or a specific sensor down to the serial number.

Use Case:

If a balluff's manager wants Distance Sensor 1 to only work on Port 1, they can achieve this. This prevents potential errors or communication issues when regular maintenance is performed. A red LED light will flash on the master if the wrong device is connected. You will also see feedback on the web server page.

10. ISDU: Index Service Data Unit

There are multiple ways to read/write ISDU’s through Balluff’s interface and clients like a PLC. Each message can contain a single command, multiple commands with the same data area size, or commands with varying data area sizes.

User Benefit:- Makes programming easier while also giving more options to configure devices in the system