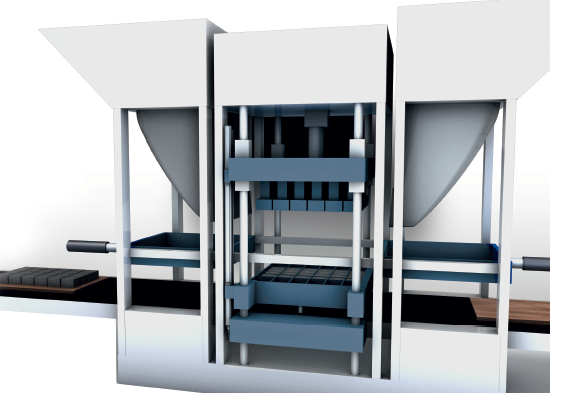

Application of the Balluff's magnetostrictive displacement transducers and injection molding machine

APPLICATION: FORMAT CHANGES

Magnetostrictive displacement transducers in rod and profile style with real-time Ethernet provide fast, precise and absolute position and speed measurement. incorporation into the control system and replacing the parameters using the defined protocols is simple and time-saving. Measurement data is sent in real time and synchronized with the process, and plug-and-play makes replacement fast and easy.

APPLICATION: PREDICTIVE MAINTENANCE

On injection molding machines Mold ID makes the use of injection molds traceable and ensures their optimal utilization. Each mold has a unique ID number, so that incorrect matches or missing molds are a thing of the past. Production cycles are also counted, which enables preventive maintenance of the molds. This extends runtime, contributes to operational reliability, increases the systems‘ productivity and improves efficiency.