BIP inductive positioning system with IO-Link interface

Modern machining centers are complex compared to those used in traditional metal

working applications. The variety of tool holders and axes often represent a hurdle

when you need to handle changing processes, ensure simultaneous processing of

work pieces and be truly efficient.

Compact, precise tool spindles, clamping cylinders and tool changers on a machining

center play a central role in the work process. Reliable and wear-free monitoring of

the clamping process in the machine system is critical. Meet this demanding challenge

simply with the new BIP04 inductive positioning system. The non-contact measuring

system in the fully potted housing will ensure the highest process reliability and automation quality, even in the harshest industrial environments.

Features:

■ High applicability: 30 × 40.5 × 18 mm form factor allows use in tight spaces

■ Flexible in usage: teachable measuring range up to 17 mm

■ Control system compatibility: analog voltage and current output as well as IO-Link interface

■ Reliable results: high linearity and precise repeat accuracy

■ High signal stability: low temperature drift

■ Secure integration: excellent electromagnetic compatibility

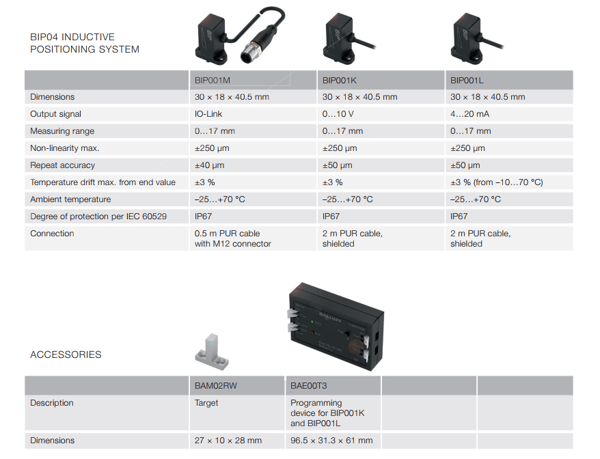

The common models are as follows: