IO-LINK product industry applications

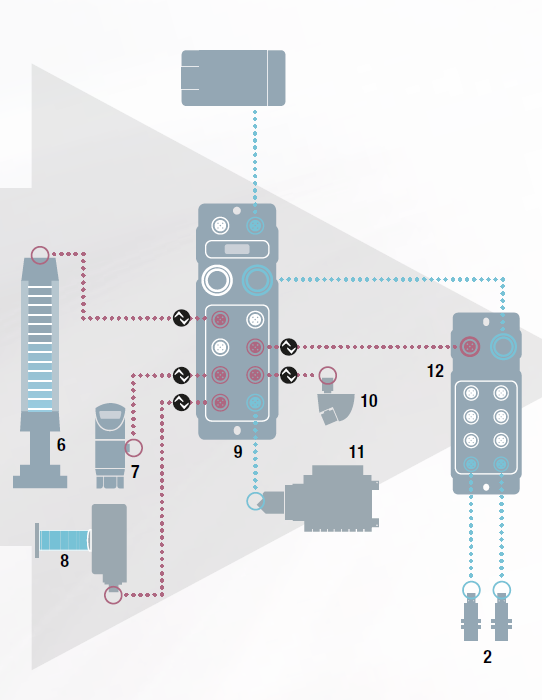

The Balluff IO-LINK product range is very broad as it is used in different industry fields. For example, in the automotive industry, welding, painting, assembly, etc.

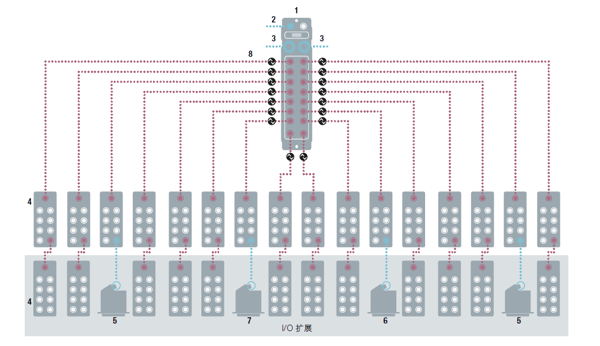

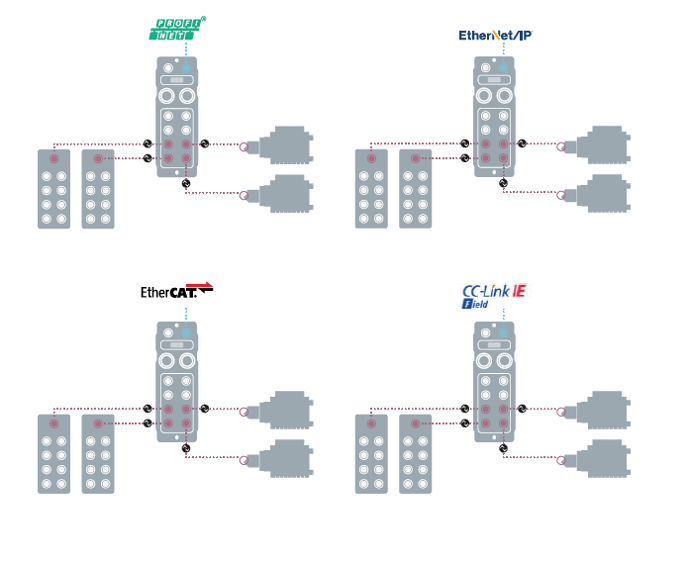

When installing this universal interface, you only need to use the IO-LINK master and industry standard 3 or 4 core standard cable. With these, you will notice that by using the intelligent communication standards that everything is quickly integrated into the fieldbus environment, and at the same time, even complex devices can be easily added.

A major feature: digital communication ensures that it can resist noise interference even without using expensive shielded cables.

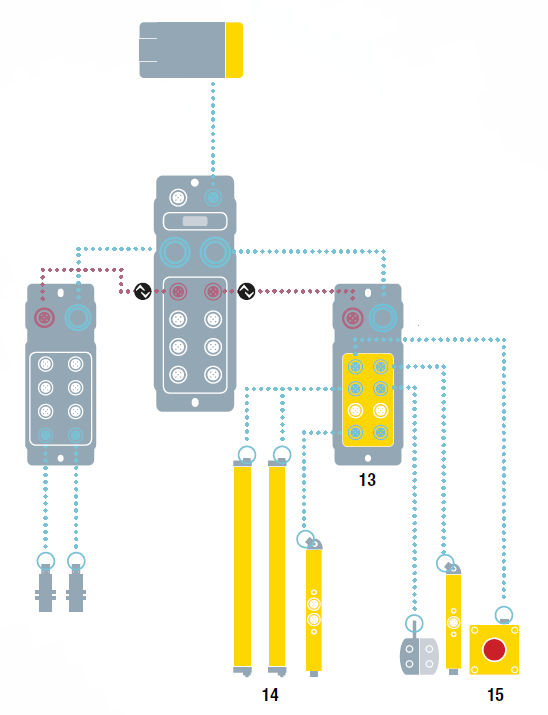

The analog signal is digitized without conversion loss. IO-LINK ensures fast and error-free sensor replacement and rapid commissioning. The parameters of the original IO-LINK sensor are automatically written from the IO-LINK master to the new sensor, thereby greatly reducing downtime.

The commissioning process, rapid replacement and data exchange are handled centrally by the functional modules of the controller. This saves time and minimizes the probability of errors.

Another advantage: IO-LINK devices will not be mixed because they are automatically recognized by IO-LINK. Through continuous diagnosis of the entire process, you can extend your maintenance interval, because the automatic adjustment through IO-LINK means that the maintenance frequency of equipment and machines is greatly reduced.

Now, even predictive error detection can be performed because all process parameters are consistently displayed on the controller.

Since it is no longer necessary to consider the accessibility of the sensor, with IO-LINK, you can place the sensor in the machine completely according to the process requirements. Process monitoring, configuration and error analysis of IO-LINK devices are now performed in the controller.

The machine operating procedures have now been optimized over time. Signal delay and distortion are reliably eliminated, because the digital transmission of data also ensures high signal quality.

With IO-LINK, you can easily meet the needs of many applications, because you can use both binary and analog standard devices with IO-LINK sensors/ actuators.