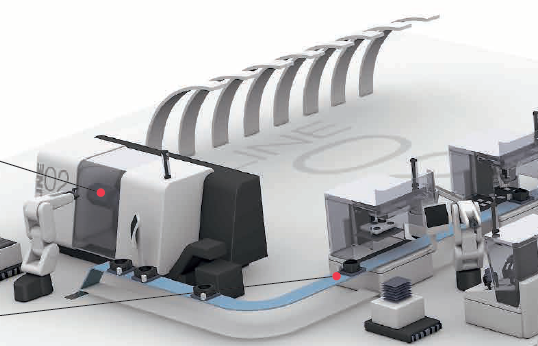

Balluff RFID technology

APPLICATION: TRACEABILITY

Poka Yoke provides transparency and targeted error management in-process by making all data traceable. Typical weak points can be identified early and counter-measures taken. This provides production security, enables fast correction runs and prompt adjustments when requirements change. RFID systems record every process step – all the production parts used, all materials and process fluids including time, location and sequence. This execution-, process- and origin information are automatically documented and are available in real time.

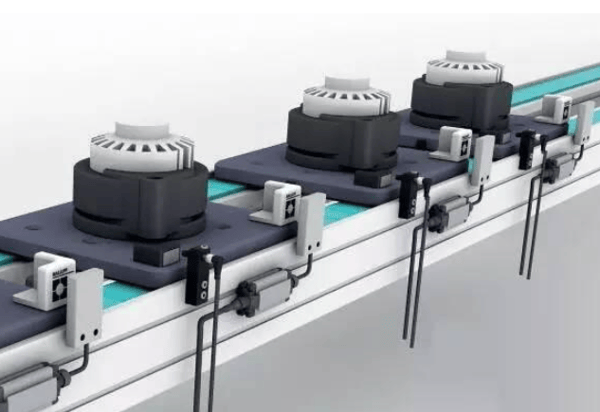

APPLICATION: QUALITY ASSURANCE

RFID collects data along the value creation chain during the entire production process, including machine number, clamping, shift, operator and batch number. In the context of quality assurance the process can be designed much more efficiently when the data need to be made available to the operator via software. For example, only workpieces from a particular production line or shift could be looked at.

Click the link to learn more about Balluff's RFID in the industry 4.0